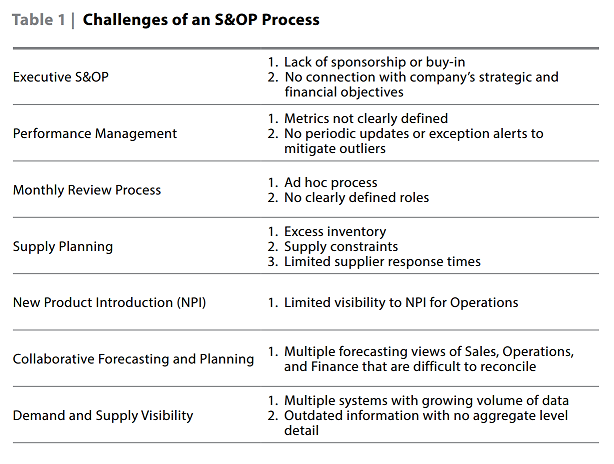

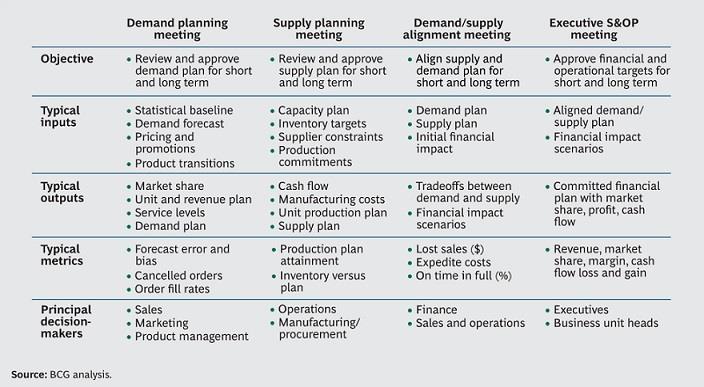

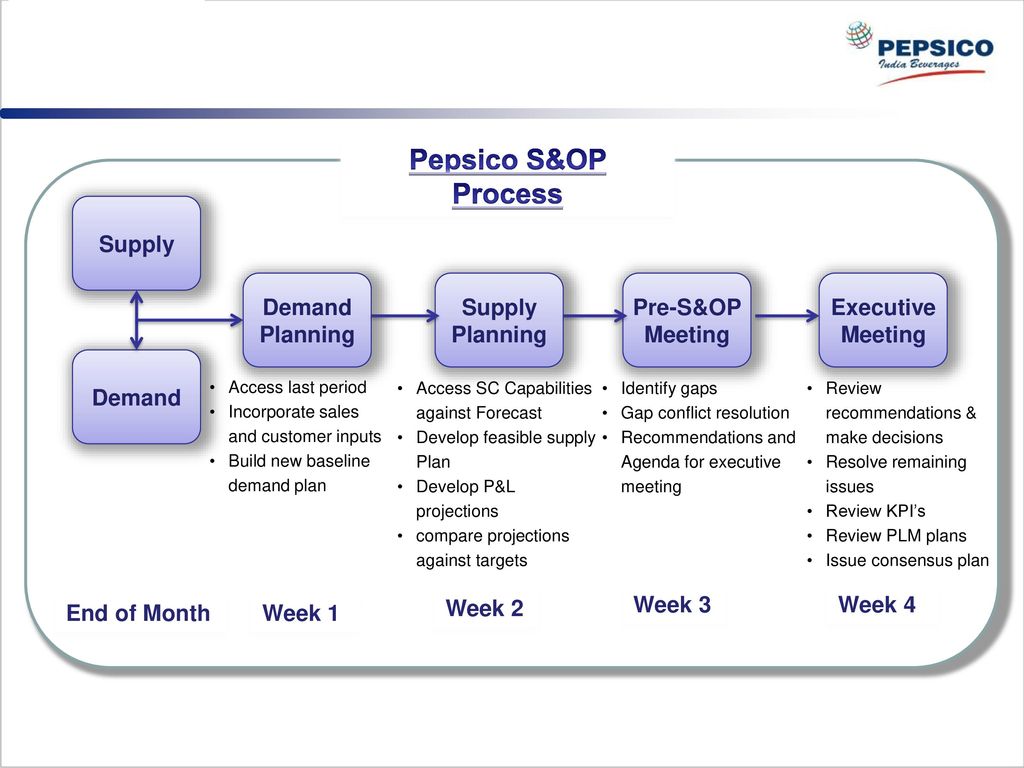

The output of the meeting is an approved demand and supply plan that can be efficiently executed by operations The S&OP leader will oversee this meeting/step in the process, but the Executive Sponsor is a required participant and will be needed to finalize all decisions/outcomes of the meeting Sample Agenda for Executive S&OP MeetingApr 01, 13 · 3 New Product Introduction Challenge Limited interdepartmental visibility in new product planning Opportunity • Increase visibility to planned launch dates and forecasts with easytoaccess tools • Make sure new product planning is included in S&OP process to align supply with demand plans 27 4PreS&OP PreS&OP is a series of meetings conducted with leaders at various levels that showcase the connectivity of plans across product, demand, supply, and finance Ideally, these meetings center around a cloudbased platform that houses all the plans in a single place

What Do Your S Op Meetings Look Like

What is s&op planning

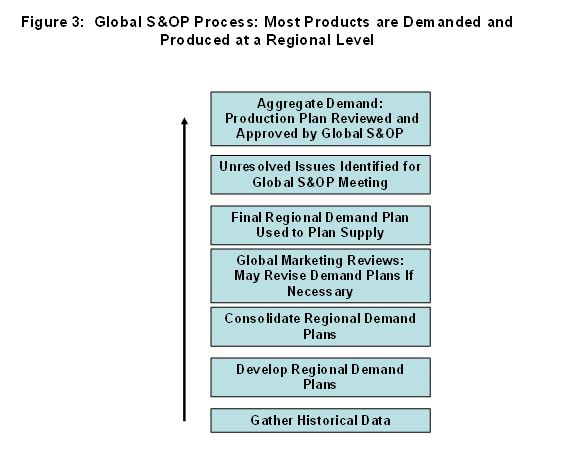

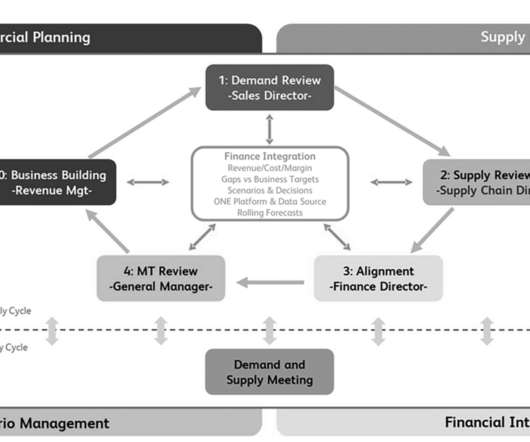

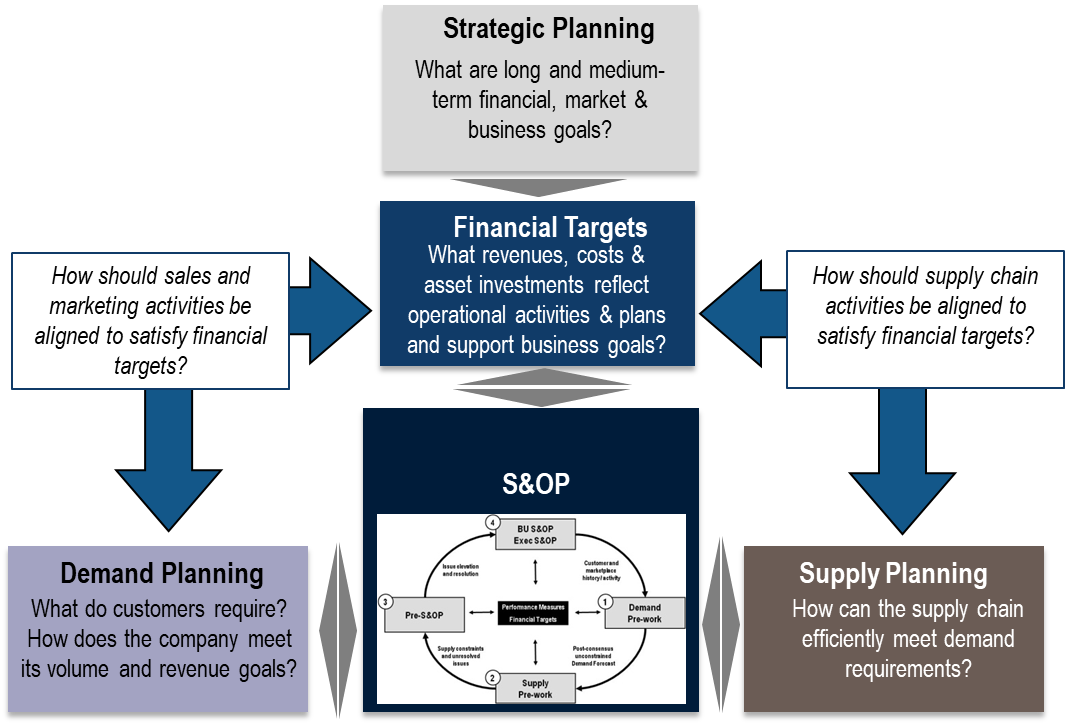

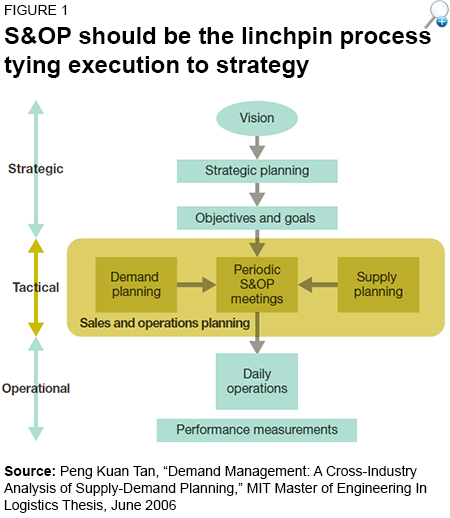

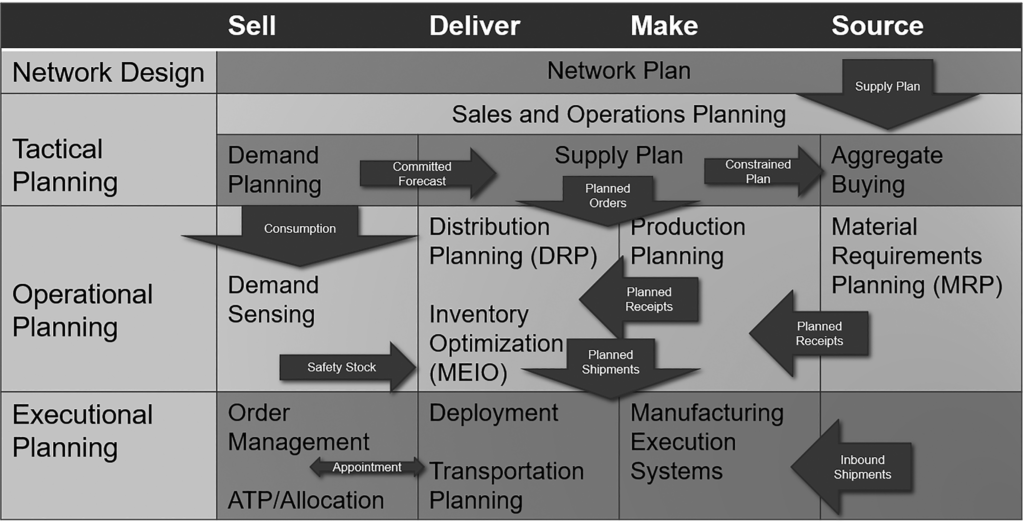

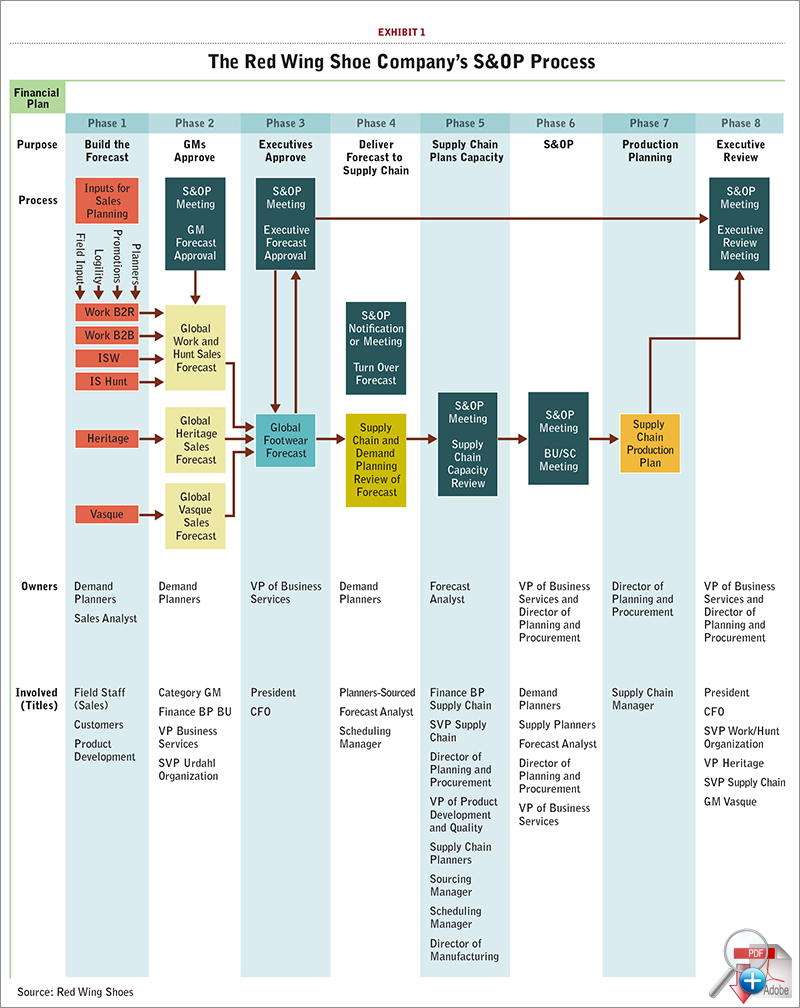

What is s&op planning-Processes, such as S&OP, that develop weekly and monthly demandsupply plans S&OP would then provide the linkage from strategy to the third type of planning, Operational Planning, that typically has planning horizons looking out up to a few weeks on a daytoday or weektoweek basis An S&OP process should have the major objective of helpingSeven S&OP Reports Every Manufacturing Executive Needs 7 2 S&OP Executive Review Dashboard This dashboard facilitates the S&OP executive review process The consensus or preS&OP meeting provides the details to the executive review process, and this dashboard provides visibility into the status of those submitted operations and supply chain plans

What Is S Op How S Op Works Demand Planning Com

Approve or change recommendations from the pre S&OP meeting for demand and supply plans, authorize any changes to plan (new machines, hire additional labor), review key performance measuresWho?Aug 13, 15 · Key Point A Sales and Operation Planning (S&OP) meeting is a meeting to design the future course of a business Yet, too many companies spend too much time talking about the past or the current period I recommend using about 6070% of the time discussing the futureSales and Operations Planning (S&OP) is a corporate practice intended to deliver superior supply chain execution by leveraging a deeper alignment with other divisions beyond supply chain most notably sales, finance and production The practice usually revolves around a monthly process starting from the sales forecasts and ending with quantified production plans

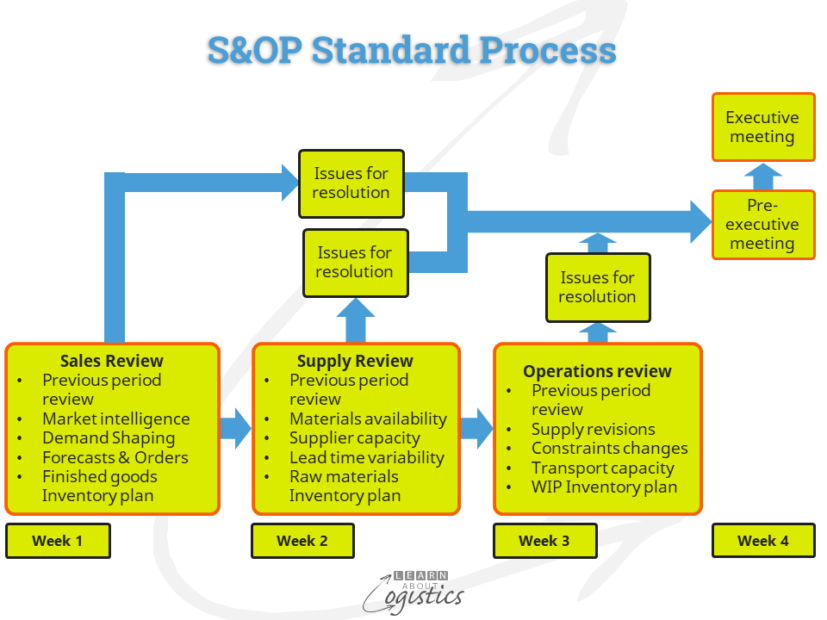

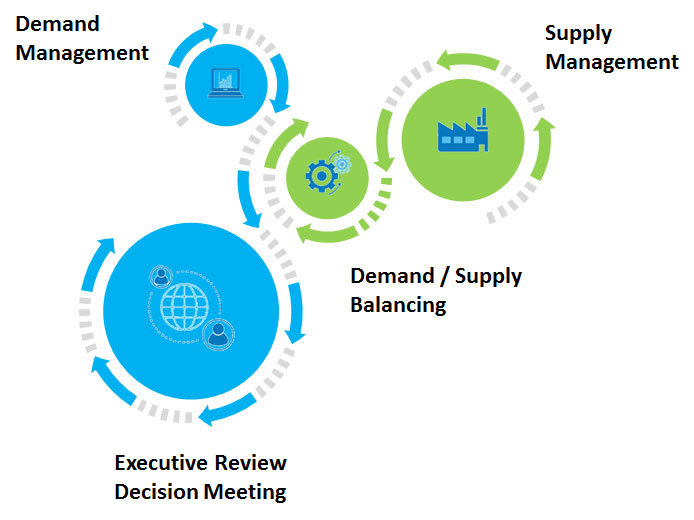

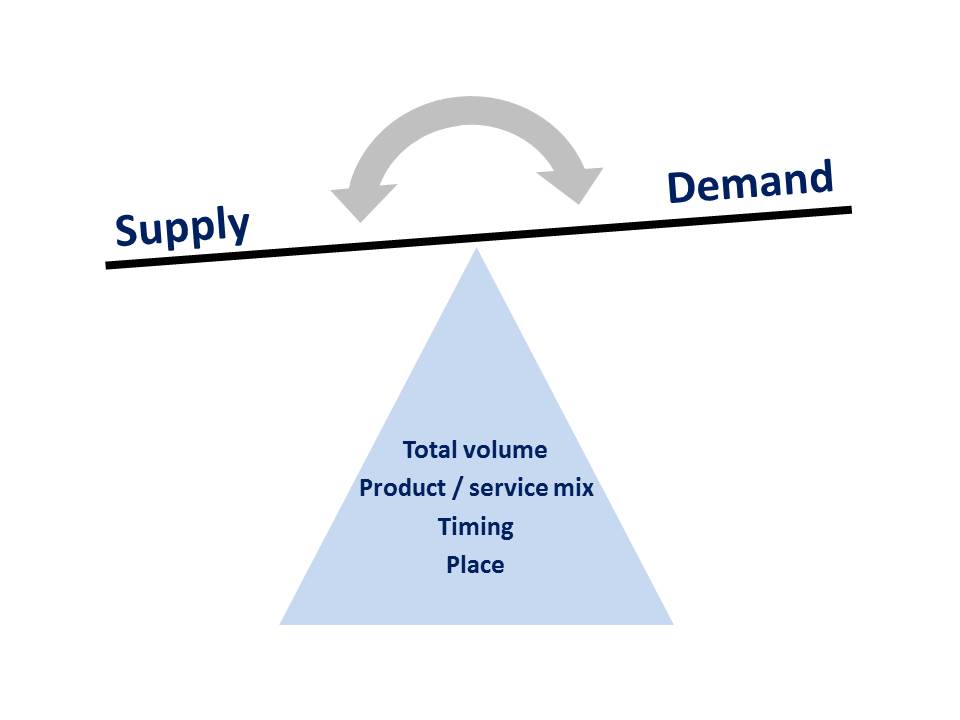

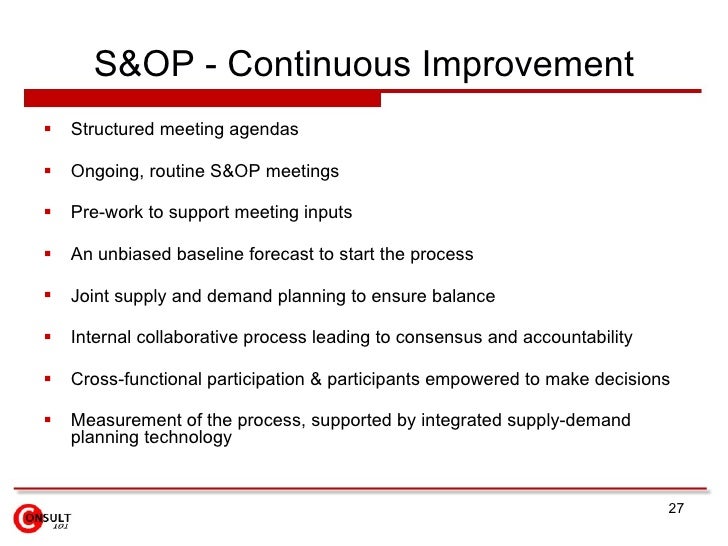

1 Ongoing, Routine S&OP Meetings A key aspect of an S&OP process is that it is comprised of routine meetings that are held on a periodic basis In terms of frequency, a decade ago, Joint supply and demand planning to ensure balance 10 Measurement of the process 11 Supported by integrated supplydemand planning technology 12 ExternalS&OP Process The S&OP process includes supply and demand planning and forecasting, combined with executive oversight With the ultimate objective of coordinating sales and operations planning, a successful result aligns every department and every business process towards aTo accomplish the demand and supply balance Sales and Operations Planning Steps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps

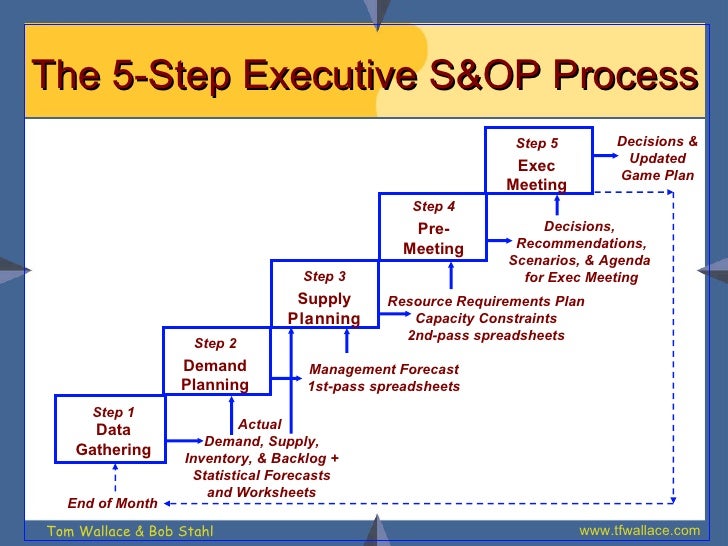

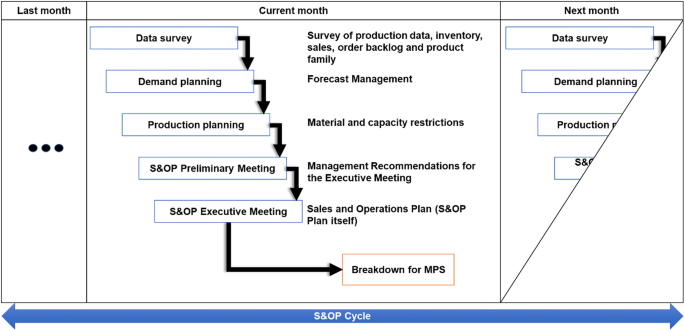

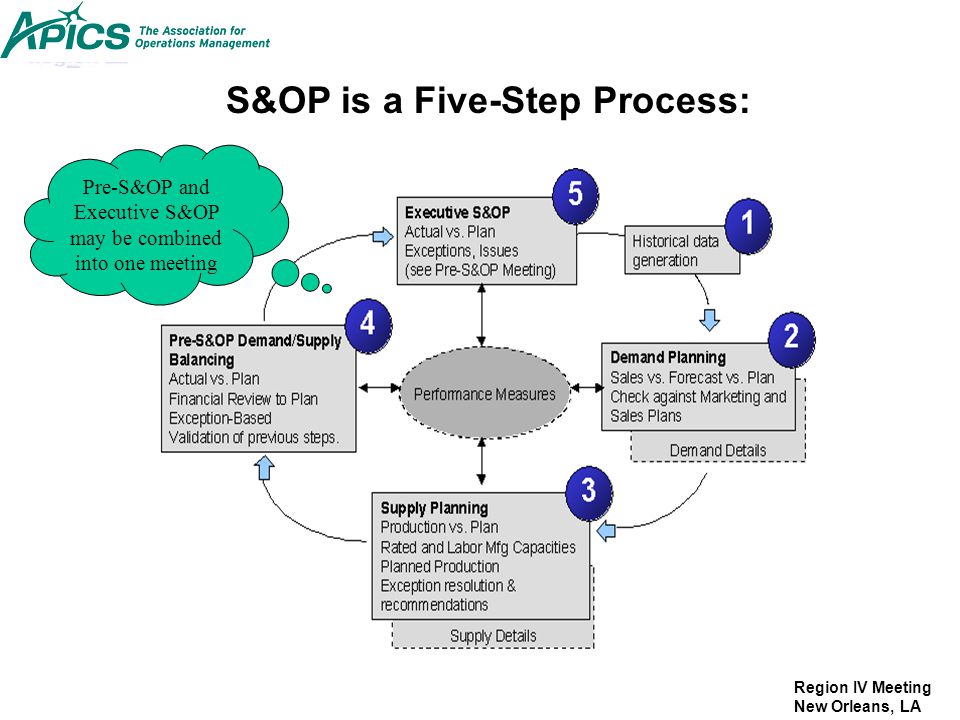

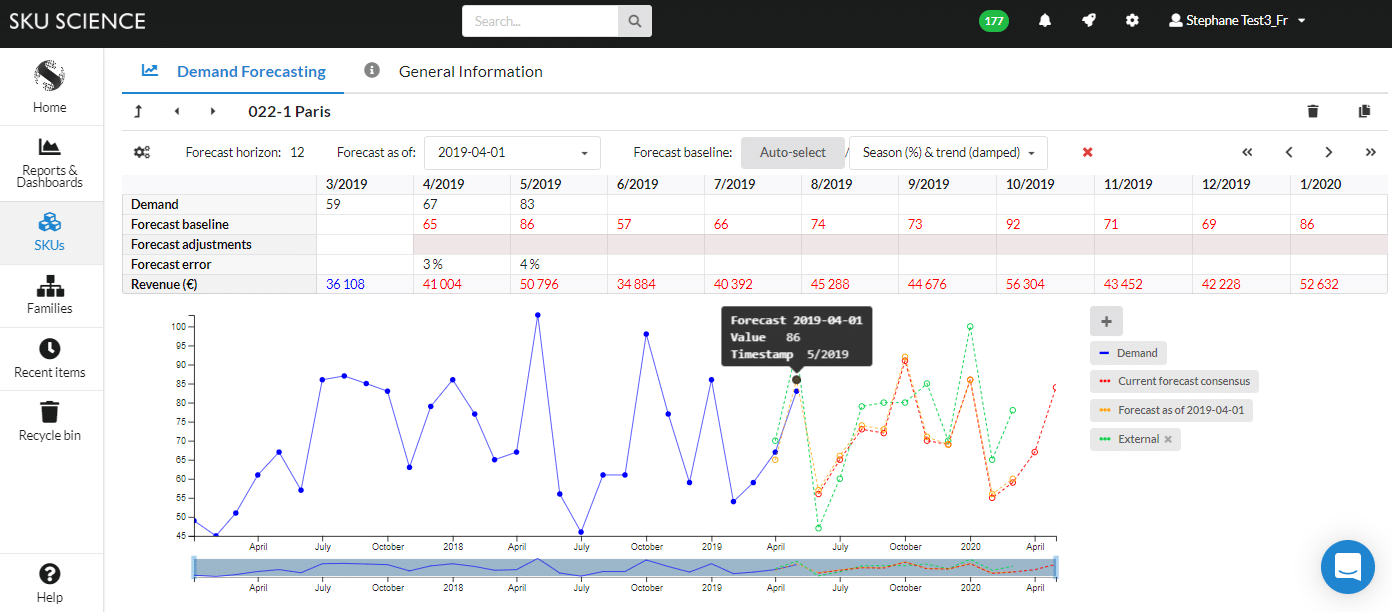

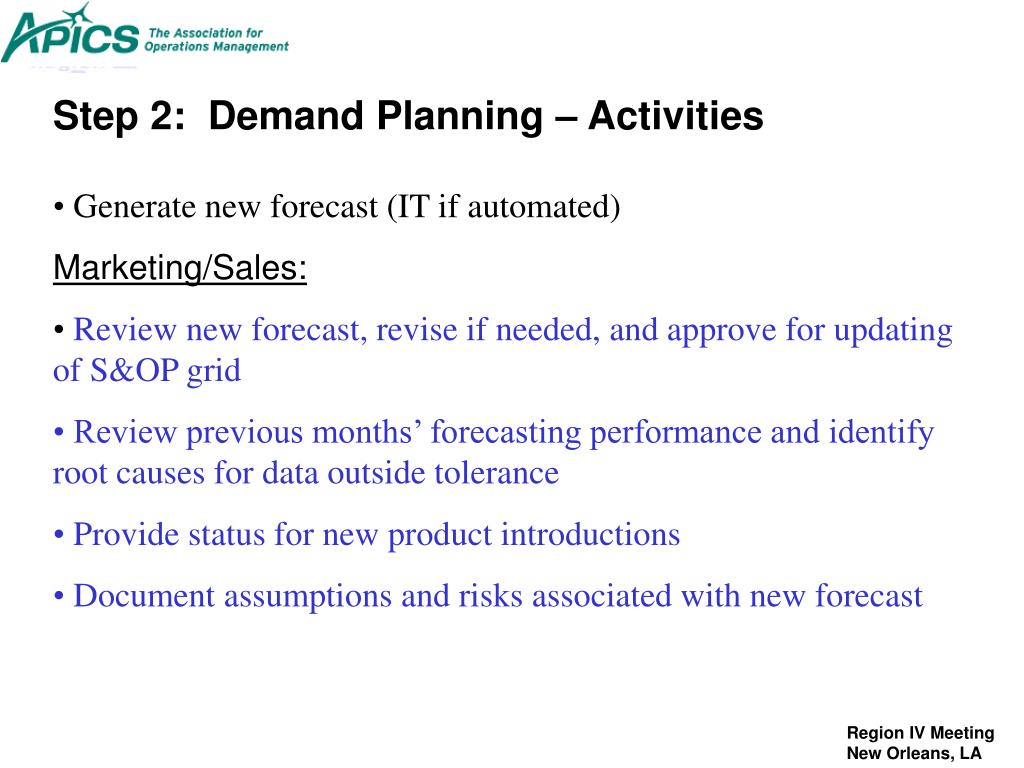

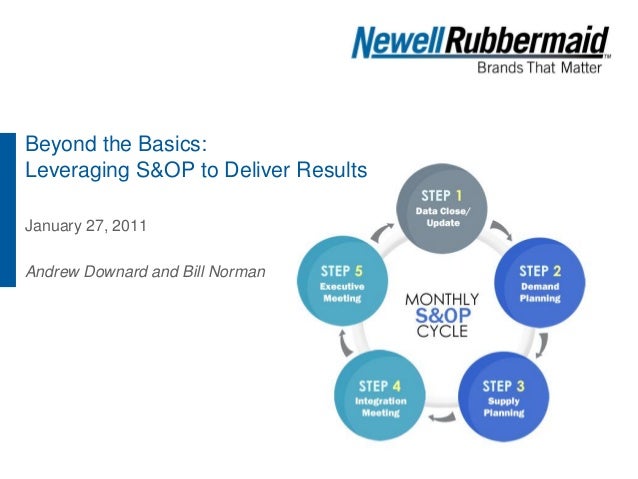

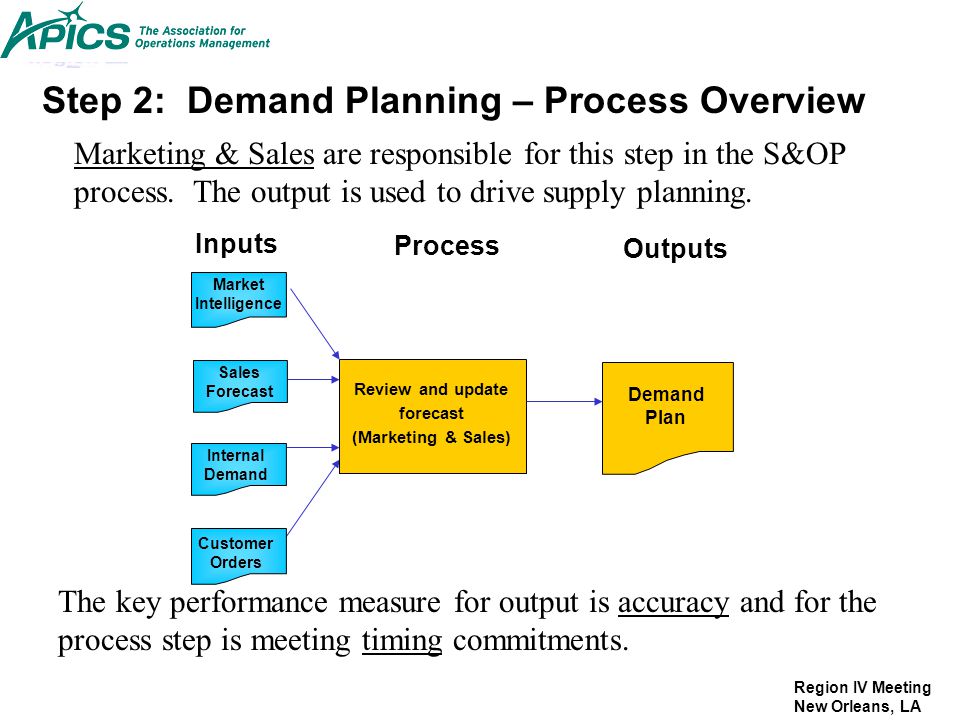

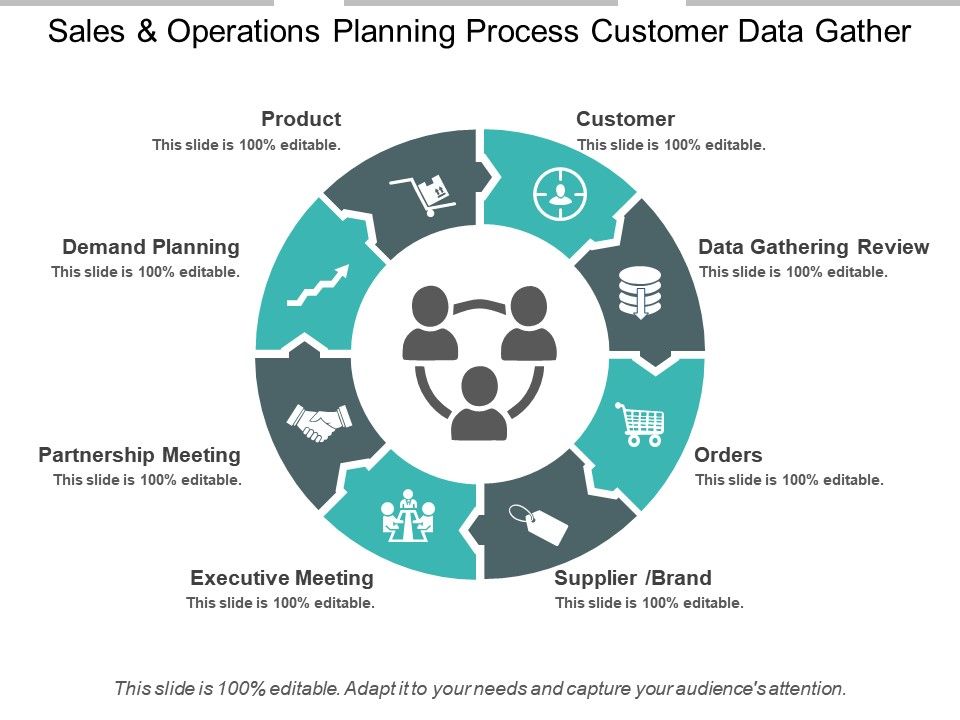

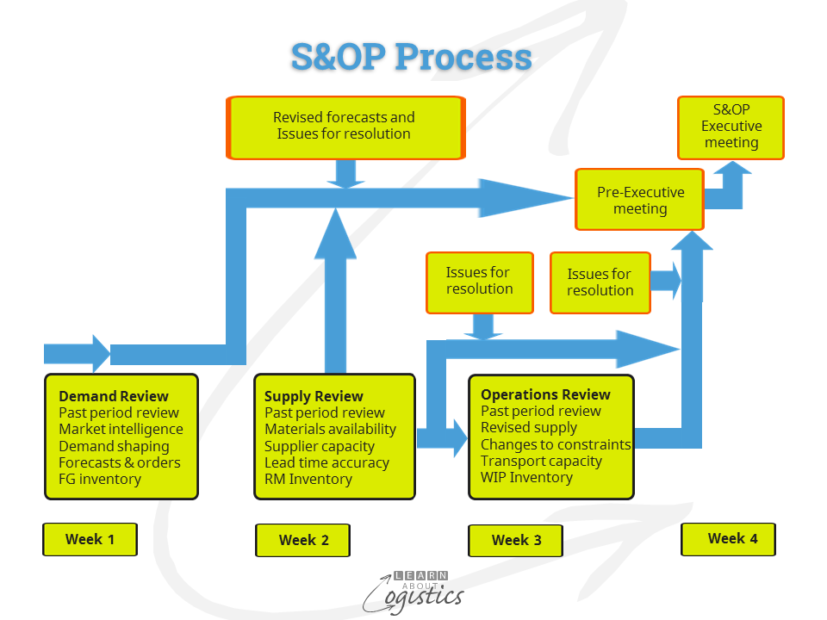

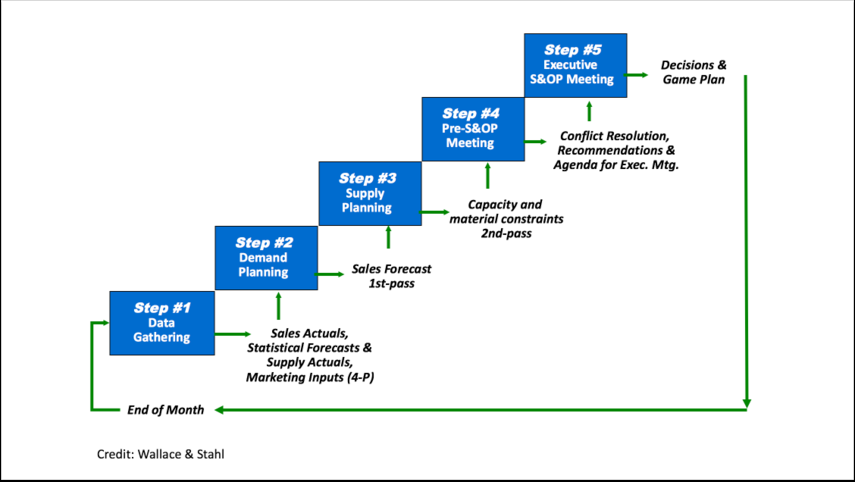

Apr 26, 18 · The demand consensus meeting is one of the most important steps in sales and operations planning (S&OP), with the resultant demand plan serving as a critical input for all other S&OP process meetings Without a demand plan as aTake S&OP to the next level with new approaches such as dynamic inventory planning and more Reconciling Perspectives 23 Exploring the central aspects of demand alignment By Bradley McCollum Explore the strategic objectives of demand alignment and the key factors ofThe S&OP process can be broken down into six essential steps data gathering and forecasting, demand planning, production planning, preSOP meeting, executive S&OP meeting, and the S&OP strategy implementation Let's take a look at each of these steps in greater detail 1

What Is S Op How S Op Works Demand Planning Com

S Op Sales And Operations Planning And Sco

Apr 29, 21 · Demand planning is a multistep process that involves several key tasks Understanding the work required within each step will allow you to create the most accurate, uptodate forecasts that will better inform your S&OP plan Below, we dive further into these steps Use past sales data to create a statistical forecastSales and Operations Planning (S&OP) is an offshoot of production planning and owes its evolution to practitioners of operations management It is looked at as an extension of aggregate planningPlanning volume mix demand supply Thus SIOP is a monthly formal balancing of supply and demand through a six to twelve month planning horizon by aggregate product families It generally includes incoming orders (bookings), backlog, shipments, forecast, finished goods inventory production and capacity

Demo S Op Management S Op Software Solution Arkieva

Best Of The Best S Op Conference

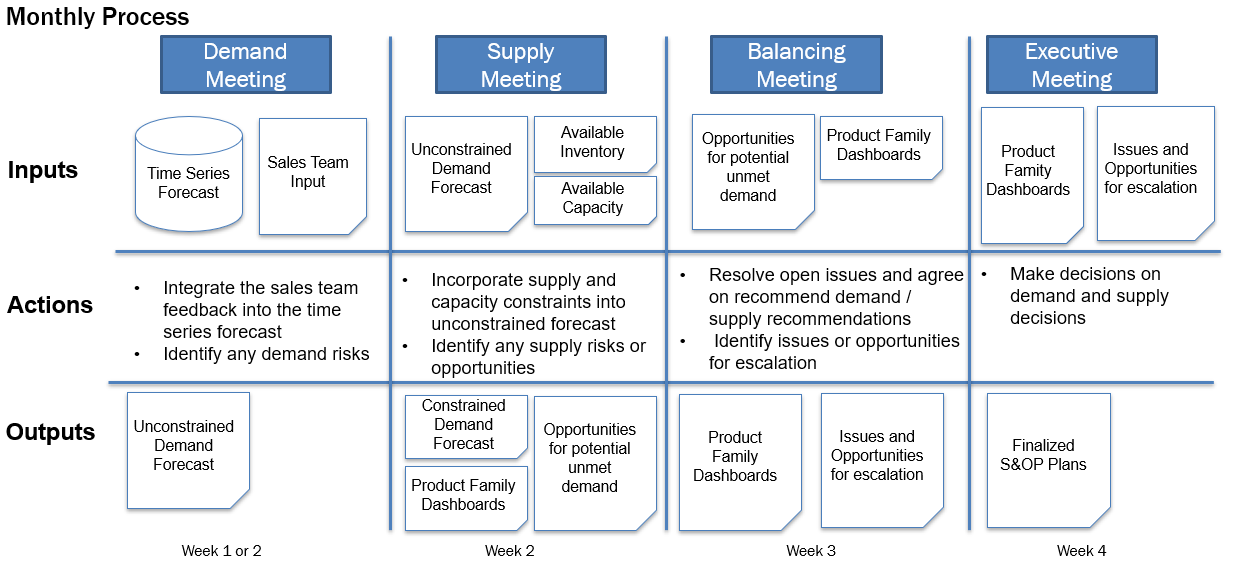

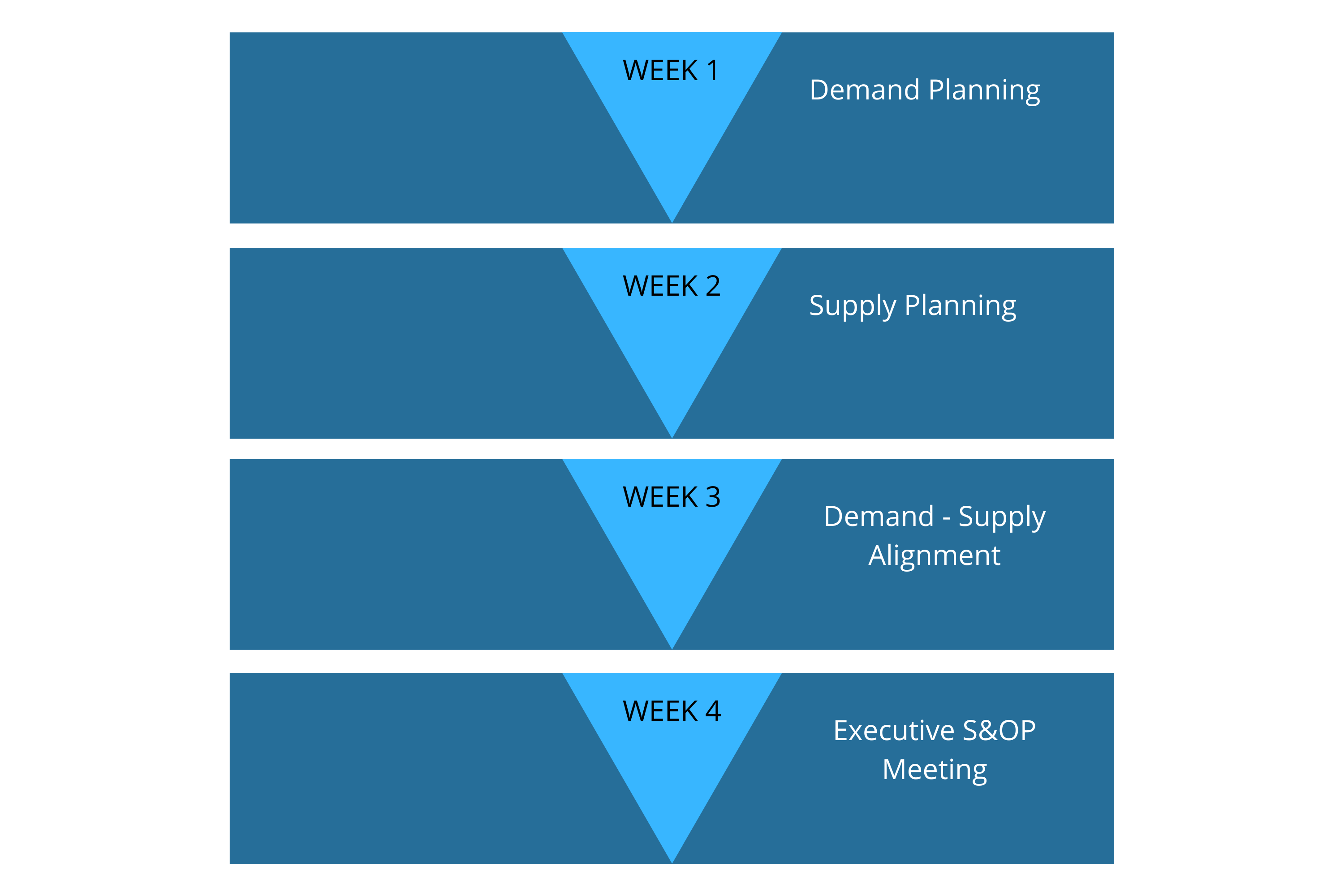

Aug 24, 17 · Pre S&OP Demand Meeting Pre S&OP Supply Meeting Pre S&OP Meeting Executive S&OP Meeting Every company will have some variation of this meeting structure Some companies may require multiple demand meetings aligned with geographic sales territories Others will have multiple supply meetings for different world areasS&OP is much more than just a meeting – it takes into account all the various planning and monitoring processes that are necessary to run a worldclass supply chain The challenge for businesses lies in capturing and summarizing the data required to support the process, and the ability to turn that data into informationAug 30, 19 · The usual meeting frequency for S&OP teams is once a month, which is not frequently enough for the operational daytoday issues of S&OE The most common S&OE setups are weekly or biweekly cycles that enable immediate course corrections and granular fine tuning Read more Brexit – Logistics Leaders Face Complexity and Cost Implications

Sales And Operations Planning Dashboard Youtube

26 Ways To Get Sales On Board With Demand Planning June 13 16 Cscmp S Supply Chain Quarterly

S&OP meetings are decision meetings – not discussion meetings The ability to make decisions is the most central element in the whole process!Sales & Operation Planning (S&OP) is a process to align an organization across all functions, so that operational capacity is optimized, balancing demand (sales) and capacity When done well, S&OP allows business to capture efficiencies in their operations and sales from the market because they can proactively adjust their business as forecastsS&OP is one of the core principles that have played a key role in optimising the supply chain during the last decade This is necessary to create a truly lea

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

Pdf Sales And Operations Planning Part I The Process Semantic Scholar

Typically, the key meetings include the Demand consensus meeting, Supply Collaboration Meeting, the General Manager Review meeting, and the Operations Review meeting In most organizations, there will be an executive Sales and Operations Planning meetingDec 11, 09 · S&OP Senior Executive Meeting Review Demand Plan (Review Product Families, Demand Assumptions) Review Supply Plan (Inventory Plan, Cost Projections, Supply Assumptions, Issue Resolution) Agree to Supply Plan (Develop Supply Chain Plans, Source, Make, Deliver) Develop Revenue Projections (Identify Gaps) 18 Month Projections Communicate Approved PlansSales and operations planning (S&OP) is a popular process that aligns a company's diverse functions while balancing supply and demand S&OP gives executives a comprehensive overview of the business so they can grasp where it stands (in all its complexity)

A Common S Op Process For Your Business Helps Planning Learn About Logistics

Sales And Operations Planning In Manufacturing Manage Collaboration Across The Entire Organization Tompkins Solutions

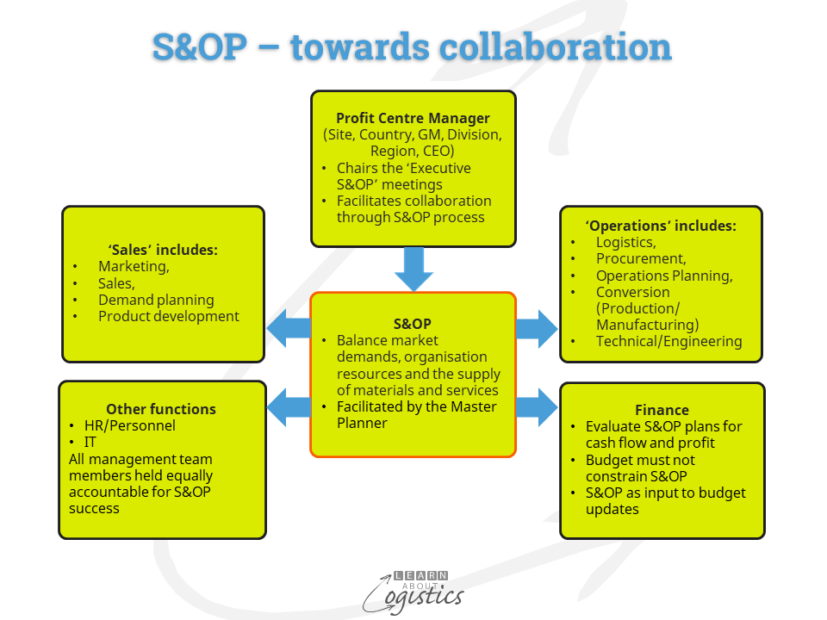

Plan Reconciliation (Pre S&OP) Match supply and demand plans with financial considerations Finalize and Release the S&OP Finalize the plan and release it to implementation The Value of Integrated S&OP The end goal of S&OP is to create a plan that unifies all demand and supply planning activities around a consensusbased planNov 13, 12 · All the planning is done in the segmentlevel S&OP process, which is made up of 26 horizontal processes Some of our clients find they have some of the 26 different horizontal planning processes already in place, at least in part The 26 are shown in Figure 54;S&OP manager typically runs meeting Team includes VP sales, VP marketing, VP SCM, VP finance, VP operations, VP product management

What Is S Op How S Op Works Demand Planning Com

Takeaways From An S Amp Op Conference

When the S&OP process is done at a scaleddown aggregatedproduct level, which is often done to make it more manageable ENABLING TECHNOLOGY ARCHITECTURE The S&OP process needs to be supported by three types of software applications 1) demandside planning, 2) supplyside planning, and 3) an S&OP workbench The components and theFeb 03, 13 · Sales and Operations Planning Process Guide STEP 4 S&OP Integration & ReconciliationPURPOSE INPUTS OUTPUTS•Resolve availability constraints •Reference to Product Portfolio •COLLABORATIVELY•Ensure plans aligned with strategy / Review • Constraints minimizedbusiness plans •Issues from Demand Reviews • Fulfillment plans alignedJun 01, 19 · S&OP is a process that coordinates different areas of the business to meet customer demand with the appropriate level of supply Implementation of S&OP should be undertaken in phases Most businesses start with a pilot program in one business unit in one country, for example

Competitive Advantage S Op Whitepaper Supply Chain Minded

My S Op Process In Jan Executive Summary In Place S Op Meetings Correct Sequence Of Meetings Demand Supply Pre S Op And S Op Meetings Ppt Download

Dec 11, 09 · S&OP – Policies Policies Planning process & how demonstrated capacities by product family will be maintained and utilised Schedule of future meetings, attendees, & an agenda for a monthly review meeting Inventory, backorder, backlog plan, planning fences, service levels, new product intro, promotion, special offers etc Product familiesJun 04, 18 · Meeting Schedule All S&OP monthly and weekly cycle meetings need to be set in advance In order for people to attend the meetings, invitations need to be sent as soon as possible One recommendation is to keep the invitations sent for the next 3 months of meetingsWeʼre also expanding to deliver endtoend professional development and education offerings through our global network of thought leadership partnerships and alliances Our newly created Supply Chain Learning Center will offer online and ondemand learning opportunities for members and customers Learn More

Mindmap For S Op And Ibp Supply Chain Movement

S Op And S Oe A Symbiotic Relationship

Mar 02, 21 · The S&OP process focuses on the tactical horizon, typically from 3 to 18 or 24 months When developing the process timing, the key point in the calendar is the existing business planning meeting This has to become the executive S&OP meeting, and the process steps leading to that have to be backward scheduled accordinglyApr 15, 16 · As you plan the agenda for your next S&OP meeting and assign action items to your team members, the process will seem like a lot of additional work and new meetings Over time, the reality is that S&OP will reduce the work and number of meetings originally caused by missed shipments, cancelled orders, capacity problems and ad hoc problem solvingSep 11, 17 · We use two primary process measurements The S&OP Assessment and the Meeting Scorecard The S&OP Assessment is similar to a school report card It is a broadbased evaluation of alignment of

Examples And S Op Supply Chain Brief

Pdf Executive S Op Managing To Achieve Consensus

Apr 17, 17 · 4) PreS&OP Meeting During this meeting the demand and supply plans are reconciled Issues are communicated Human Resources and Financial first recommendations are drafted 5) S&OP Executive MeetingS&OP Helps Balance Demand and Supply Demand Planning, with the major output being the Demand Plan, is just one important aspect of S&OP We still need to look at other tradeoffs like balancing our demand with our supply capabilities With a more mature S&OP process, it is about managing tradeoffs like these and other functions throughS&OP in the Real Time Value Network™ links your organization's multiyear strategy plan, annual operating plan, and monthly S&OP plans with tactical sales, marketing, and financial goals, while providing the ability to execute across your operations and key trading relationships

Advanced Planning System As Support For Sales And Operation Planning Study In A Brazilian Automaker Springerlink

Sales And Operations Planning Report Do You Get Surprises

Under this type of S&OP process the planning processes are integrated so that demand and supply plans are aligned jointly by demandside and supplyside organizations A single roughcut demand plan is developed and brought into the S&OP meetings In addition, a single roughcut supply plan is aligned to the roughcut demand plan, and it isEven though the HANA engine allows running simulations directly at the S&OP meeting, it is still recommended that focus is on decisionmaking and information rather than dataJun 01, 19 · Demand planning and forecasting are not stand alone processes They must be integrated into other aspects of operations in order to provide value One of these processes is S&OP The Institute of Business Forecasting defines S&OP as "a process that integrates demand, supply, and financial planning into one game plan for business

Information Sharing For Sales And Operations Planning Contextualized Solutions And Mechanisms Sciencedirect

Insights European Gateway Eg Newsroom

All are pulled together in the segment S&OP meeting

Proactively And Reactively Managing Risks Through Sales Amp Operations Planning Emerald Insight

Connecting Strategy And Operation Through S Op Visagio Management Engineering

S Op Demand Planning Forecasting Masterclass 21 Live Online

You Simply Need To Know What Do Next

Sales Operations Planning Two Decades Of Learning At Basf Ppt Video Online Download

How To Get Your S Op Process Right Sku Science

Evaluation Of The Maturity Of The S Amp Op Process For A Written Materials Company A Case Study

Scm Portal Insight The Five Steps Of S Op Process

Sales Operations Planning S Op Pdf Free Download

What Is S Op How S Op Works Demand Planning Com

S Op Google Search Meeting Agenda Template Agenda Template Sales And Operations Planning

Session 2 Forecasting And The Sop Demand Forecasting

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

Ppt Sales Operations Planning Two Decades Of Learning At Basf Powerpoint Presentation Id

Fixing An Overly Complicated Sales And Operational Planning Process Supply And Demand Chain Executive

Corporate Decision Making S Op And Beyond Enterra Solutions

Dp Vs S Op Process Flow

What Do Your S Op Meetings Look Like

Demand Planning Vs Supply Planning Balance Is The Key To Success Plex Demandcaster

Apics Principles Of Sales Operation Planning S Op Knowerx Top Level Partners Of Apics

View Of A Sales And Operations Planning Application In The Brazilian Subsidiary Of A Multinational Chemical Company Brazilian Journal Of Operations Production Management

Achieve Excellence In Sales And Operations Planning Sapinsider

How To Make The S Op Process More Robust Demand Planning

S Op Implementation Roadmap

S Op Education Program Chainsequence Inc

Sales And Operations Planning Explorescm

Who Owns S Op By Accenture Strategy Guest Blogger

S Op Sales And Operations Planning And Sco

The S Op Meeting Scorecard Measuring The Fundamentals Of S Op

Sales And Operations Planning S Op Logistiikan Maailma

S Op Sales And Operations Planning And Sco

S Op The Evolving Supply Chain Lifeline Supplychainomics

Global S Op Forecasting Business Planning Summit Conferenzia World Professional Conference And Event Organizer

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

How S Op Improves Your Organization Tmc Fr

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

23 S Op Ideas Sales And Operations Planning Supply Chain How To Plan

S Op Effectiveness Recommendations To Make The Leap Sales And Operations Planning Capacity Planning Planning Process

What Is S Op How S Op Works Demand Planning Com

Involving Execution Managers With Sales And Operations Planning Supply Chain 24 7

What Is S Op Or Sales Operation Planning Sales And Operation Planning Definition And Steps

7 Reasons Why S Ops Fail Supply Chain Analytics Planning Optimization Software Solvoyo

S Op Process Challenges In Beverage Industry Ppt Video Online Download

Sales Operations Planning Consulting Supply Velocity

What Are The Basic Elements Of The S Op Process Quora

Beyond The Basics Leveraging S Op To Deliver Results Newell Rubberm

Sales Operations Planning Two Decades Of Learning At Basf Ppt Video Online Download

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

Benefits That Sales And Operations Planning Brings To Your Organization S Supply Chain By Group50consulting Issuu

What Is One Plan S Op Arkieva

5 Reasons Why Sales And Operations Planning Is Important Scmdojo

A Case Method For Sales And Operations Planning A Learning Experience From Germany

Demand Management Springerlink

S Op Sales And Operations Planning Demand And Forecast By Achain Management Issuu

Is Your S Op Meeting Mostly About The Past And The Present Supply Chain Link Blog Arkieva

Mindmap For Sales Operations Planning 2 0 Supply Chain Movement

Sales Operations Planning Engagement Model Tvo Maine Pointe

S Op Made Practical The European Business Review

Sales And Operations Planning Process Customer Data Gather Powerpoint Slide Templates Download Ppt Background Template Presentation Slides Images

Optimize Sales And Operations Planning S Op With Slim4 Slimstock

How Can Demand Management Drive Your Sales Operations Planning Moore

Sales And Operations Planning S Op

Implement The S Op Process For Supply Chain Success Learn About Logistics

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

Oracle Demantra Sales And Operations Planning User Guide

S Op Implementation Roadmap

Supply Chain Graphic Of The Week The S Op Process

Top 11 Sales And Operations Planning S Op Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Sales And Operations Planning S Op 101 Smartsheet

Sales And Operations Planning S Op Logistiikan Maailma

Sales Operations Planning S Op Demand Planning Cargo

Sales Operations Planning A Proven Business Process Learn About Logistics

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

26 Ways To Get Sales On Board With Demand Planning June 13 16 Cscmp S Supply Chain Quarterly

0 件のコメント:

コメントを投稿